What is polycarbonate?

Polycarbonate is durable, lightweight, with a high impact-resistance.

It’s a great alternative to glass.

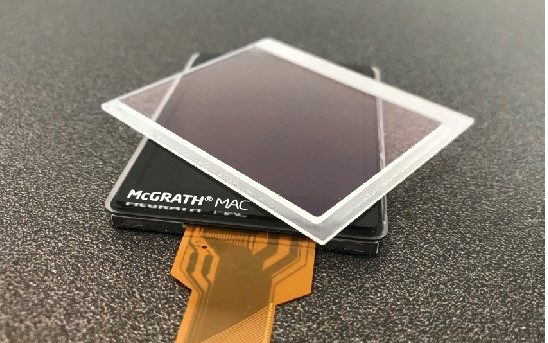

Leading development of electronic display screens, replacing glass with hard coated polycarbonate.

Although it has a high impact-resistance, unfortunately it suffers when it comes to scratch resistance.

However, applying an abrasion resistant hard coat to polycarbonate provides a harder surface.

This enables it to be used in a wider variety of applications.

What are the benefits of hard coated polycarbonate?

Benefits of hard coated polycarbonate include:

- Double side hard coated for maximum protection

- Improved Optical transmission over standard polycarbonates

- Excellent print adhesion achieved

- Outstanding machining properties

- Sheet size: 975mm x 950mm

Which hard coated polycarbonate should I choose?

As we know, adding a hard coat to polycarbonate broadens its uses.

But which hard coated material should you choose?

Soni™ Optical Grade Hard Coated Polycarbonate is exclusive to Panel Graphic.

It provides abrasion resistance:

Making it the obvious substrate choice for electronic display screens that are exposed to harsher environments.

It’s available in multiple thickness from 0.5mm, in single or double sided coatings.

It’s the only reliable choice when quality really matters.

Extensive testing

The Soni™ Optical Grade Hard Coated Polycarbonate has gone through extensive in house testing.

Passing all of our criteria:

- Excellent Ink adhesion “even direct to hard coated surface”

- Transparent ITO conductive coatings can be applied “achieving a highly conductive hard coating”

- Long term high performance wear resistance “with no visual surface defects”

- High optical Clarity “achieving the highest optical quality available on Polycarbonate”

Why Panel Graphic is the solution for you?

As mentioned, Soni™ has outstanding machining properties.

We have several CAD trained technicians throughout the company, using platforms such as Solidworks® Artcam® Corel Draw® to name a few.

Whether you have requirements for prototypes or full scale production, Panel Graphic are the team for you.

Not to mention, we house 8 x Datron M8 Cubes in environmentally controlled manufacturing suites. Plus, large format CNC cutting tables with a capacity up to 3.5m x 2m.

Panel Graphic are well placed to meet all your requirements. Find out more benefits of hard coated plastics.