If you search for scratch resistant plastics, you’ll find it everywhere… in product specifications, marketing copy, and customer enquiries. And we understand why. When a plastic surface marks easily, it affects performance, appearance, and ultimately confidence in the product.

But here’s the honest truth: there’s no such thing as a truly scratch-proof plastic.

What does exist; and what actually matters is abrasion resistant plastic.

Scratch Resistant vs Abrasion Resistant Plastics

The term scratch resistant plastic is commonly used to describe materials that can better withstand everyday wear, scuffing, and repeated contact. Technically, this resistance comes from abrasion-resistant coatings, not the base plastic alone.

Uncoated plastics, even high-performance ones, will mark over time. The difference lies in how well the surface resists repeated mechanical contact, such as:

- Fingernails and keys

- Repeated cleaning

- Industrial handling

- Environmental debris

- Frequent user interaction

This is where abrasion resistance becomes critical.

How Abrasion Resistant Coatings Improve Plastic Performance

By applying specialist surface coatings, plastics can be engineered to perform far beyond their natural limits. Abrasion resistant coatings:

- Significantly reduce visible scratching

- Extend product lifespan

- Maintain optical clarity and surface finish

- Improve resistance to chemicals and cleaning agents

- Enhance user experience in high-touch applications

These coatings are commonly used on display windows, control panels, automotive interiors, medical devices, industrial equipment, and outdoor applications – anywhere durability and appearance matter.

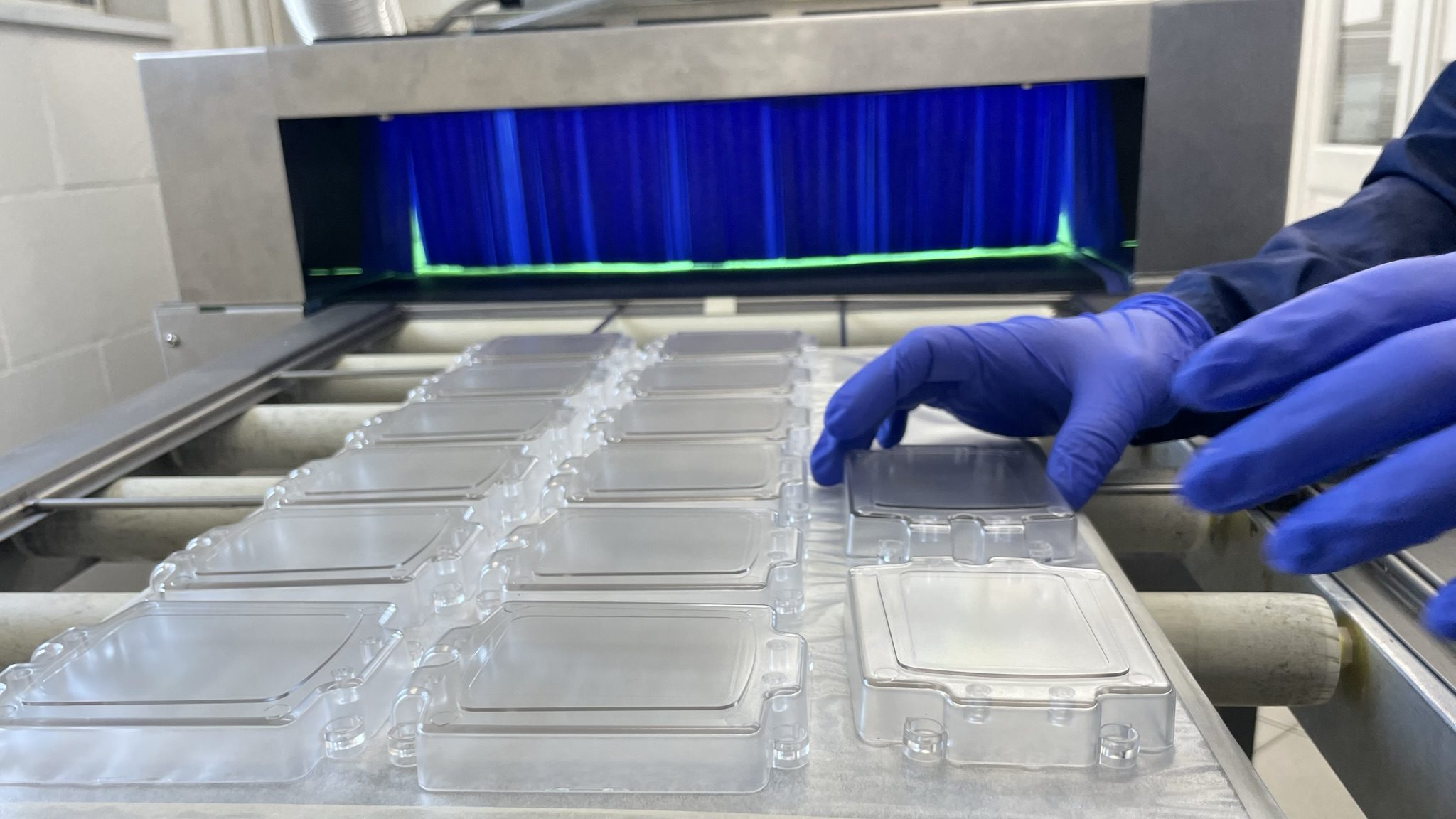

Watch the below 60 second video to see our Optiguard™ surface coatings in action:

Choosing the Right “Scratch Resistant” Plastic Solution

When customers ask for scratch resistant plastics, what they usually need is a plastic solution designed for real-world use; one that balances clarity, durability, and long-term performance.

The key isn’t eliminating scratches entirely (because that’s unrealistic), but dramatically reducing surface damage over time through:

- Correct material selection.

- Purpose-designed abrasion resistant coatings.

- Application-specific testing and validation.

Optiguard™ Chemical & Abrasion resistant surface coatings by Panel Graphic

Optiguard™ Surface Coatings for Plastics will dramatically reduce scratching when applied to acrylic or polycarbonate sheets or mouldings giving a surface hardness approaching that of glass together with superior resistance to chemical attack.

All Optiguard coatings are suitable for internal and external use but it is recommended that UV stable substrates be used when exposed in direct sunlight.

Our coatings are available in a Clear gloss, or a matt / anti-glare finish. They can be applied to flat sheet or mouldings.

Designed for Real Use, Not Just Specifications

At Panel Graphic, we focus on engineering plastics that perform better in the environments they’re actually used in. By combining optical-grade plastics with advanced abrasion resistant coatings, we help customers achieve the durability they expect when searching for scratch resistant plastics – without compromising on transparency, colour vibrancy, or usability.

If you’re designing a product where surface durability matters, it’s worth looking beyond the terminology and focusing on the performance that really counts.

Because better plastics don’t just look good on day one… they stay that way.

With over 25 years of experience in optical plastics, coatings, and display enhancement, Panel Graphic continues to push boundaries – helping manufacturers deliver displays that look sharper, last longer, and perform better.

Contact the team today: sales@displaywindows.com OR give us a call on 01508 528 028