At Panel Graphic, we’ve spent over 25 years perfecting the art of printing on rigid substrates—specifically printed plastics and printed glass—to meet the needs of demanding industries like automotive, marine, aerospace, and technology.

Why Print on Glass and Plastics?

Printed glass and printed plastics provide the perfect balance of visual clarity and robust performance. Whether you’re designing a user interface for an electric vehicle or an information panel for a museum exhibit, these materials—especially when coated—stand up to wear, weather, and constant use.

Printing Methods We Use

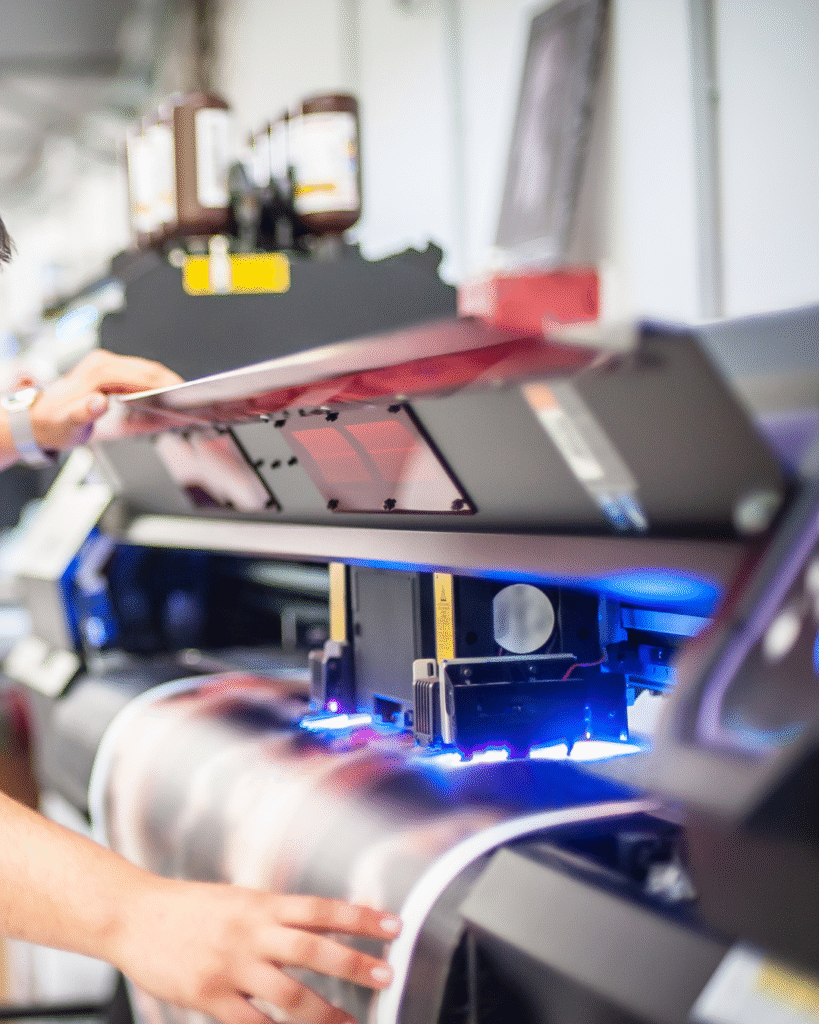

UV Digital Printing

We use UV-curable inks to print directly onto coated plastics and coated glass, offering crisp detail and rapid turnaround. This method is ideal for custom display windows, branded components, and one-off prototypes.

Example: Custom-printed Solaris™ acrylic windows for touchscreen kiosks and digital signage units. A perfect solution for pre-production samples.

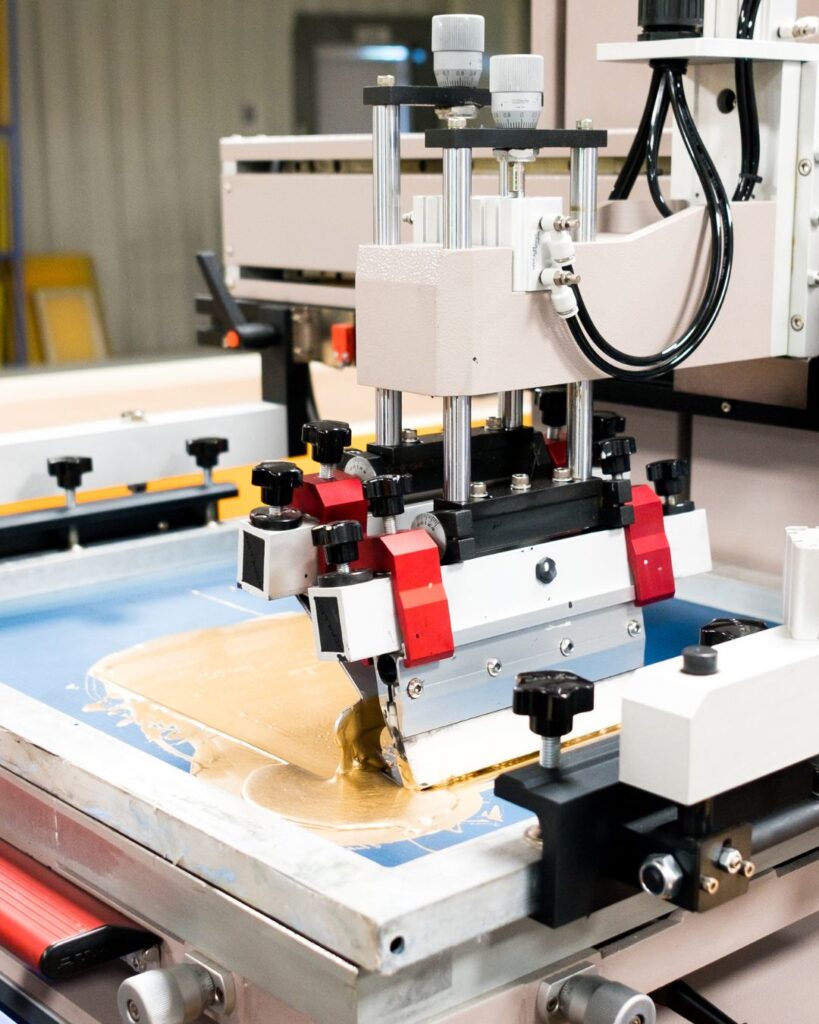

Screen Printing

For larger runs or projects requiring block colour and excellent ink opacity, we turn to traditional screen printing. It’s particularly effective on clear or tinted acrylics and polycarbonates.

Example: Automotive control panels and displays with silk screen-printed detail, used in high end automotive interfaces. Find out more about our work in the automotive sector here.

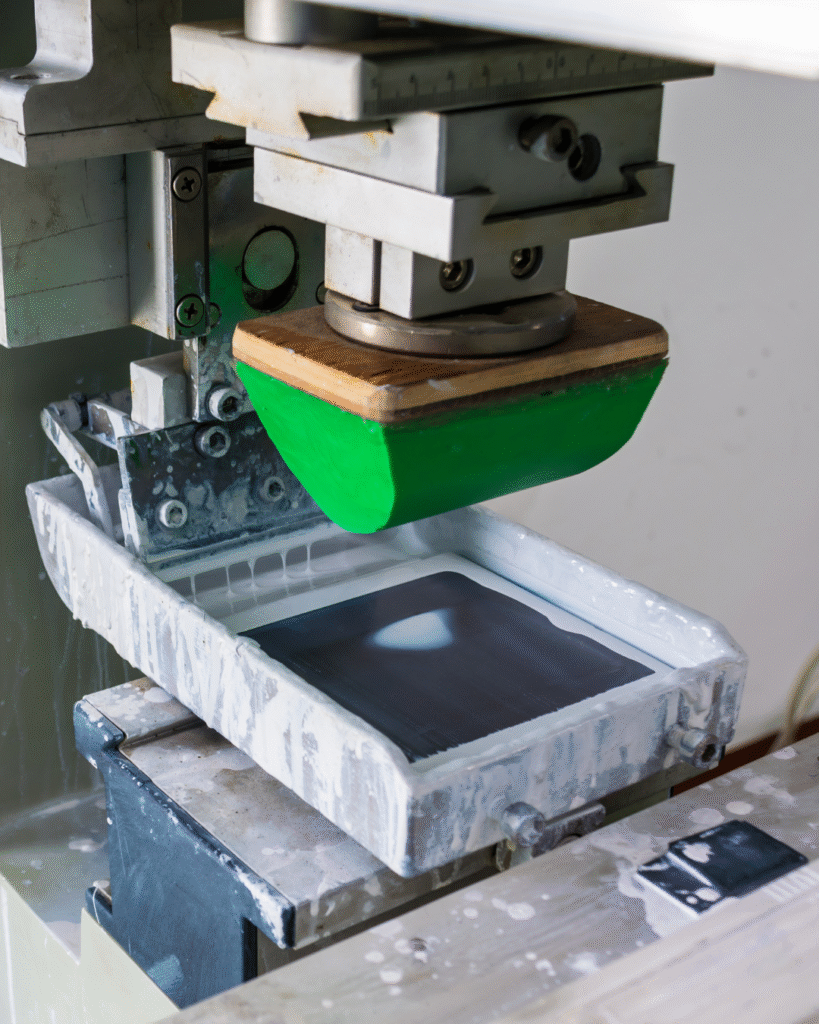

Pad Printing

Used for smaller, irregular components like plastic mouldings or CNC-machined housings, where precision is key.

Example: Automotive control buttons with a convex face, using the machines pad to get full coverage of the curved face of the part.

Ceramic Printing (Glass Only)

For architectural or high-temperature use cases, we can help customers source or specify ceramic printed glass that’s kiln-fired for longevity.

Why Coatings Matter

We don’t just print—we enhance. Our in-house Optiguard™ coating range transforms everyday plastics into performance-ready solutions:

- Optiguard™ Hard Coat – Abrasion and chemical-resistant

- Optiguard™ AR – anti-reflective, perfect for sunlit environments

- Optiguard™ Clean – anti-fingerprint and easy-clean for touchscreen use

The Panel Graphic Advantage

Every project is custom, and every substrate we print is selected and treated for its final environment. Whether you’re looking for printed plastics that pop with colour or coated glass that withstands the elements, we’re here to help you deliver performance with style.

At Panel Graphic, we provide turn-key solutions for high-performance glass components, tailored to demanding industries.

Whether you’re in transport, retail, medical, or industrial design, our expertise helps you deliver ready-to-use, reliable results—from concept to final assembly.

Contact the team today: sales@displaywindows.com OR give us a call on 01508 528 028